The application of steel belt in food industry

1. Steel belt type baking system;

2. Steel belt cooling system;

3. Suitable for cooling granulation production system;

4. Quick-freezing equipment for meat, seafood and coffee concentrate;

5. Dehydration and drying equipment for fruits and vegetables;

6. Food cooking line;

7. Steel belt and steel belt conveyor system.

Our products

ASS-1000 duplex stainless steel.

ASS-1200 austenitic stainless steel.

CS1100 tempered carbon steel.

CS1300 tempered carbon steel.

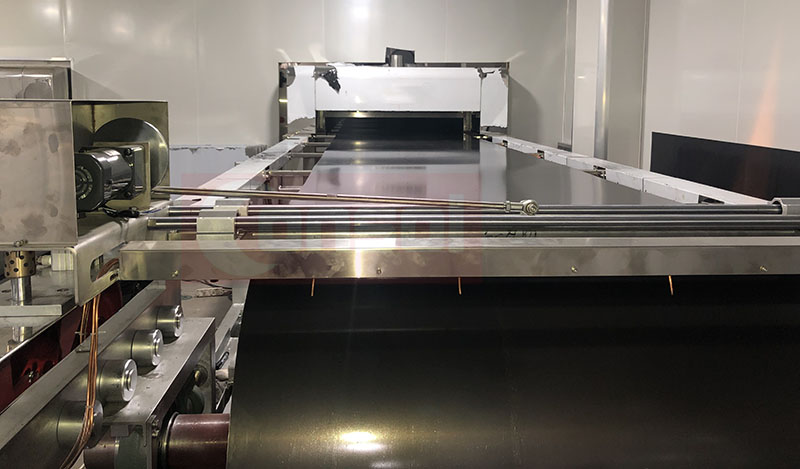

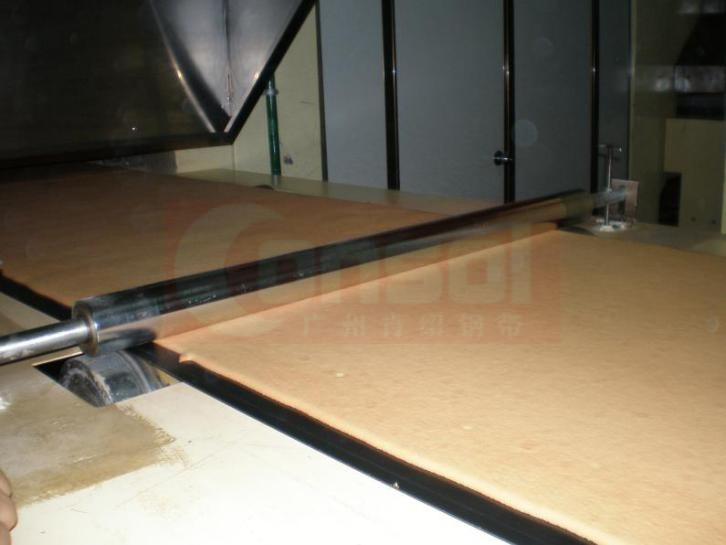

Steel belt baking system

Application scope:

Suitable for biscuits, chocolate, nuts, white white, dense cake, bread, pasta crackers, muffins, brownie, puff, cookies, crackers, oatmeal crisp, gingerbread, valley bar, Christmas Gingerbread, Marin sugar, macarons, cake, pizza, Sponge Cake food production process.

Swiss roll, tiger skin cake

In addition to the steel belt, Consol also provides the components of the conveyor system:

Steel belt cooling system

To meet the needs of cooling applications such as chocolate, candy, mashed potatoes and agar, we have three cooling systems to choose: water cooling, freezing gas cooling, and airflow cooling. Our engineers will work together with you to set up a cooling solution according to your products,including the complete system of feeding and discharging.

System suitable for cooling granulation production

The final shape of the solidified and crystallized product depends on the feeding and unloading device. Therefore, we provide a number of equipment to ensure that the product features can be effectively matched with the processing, appearance and other processing requirements. These forming equipments include bar forming machine, chip overflow channel, and professional steel belt granulating system. An accurate granular material forming equipment produces uniform size, easy to handle and dust-free granular material of 1 to 40mm diameter.

In a variety of different products, has confirmed that suitable for steel granulation production systems: chocolate, candy, gum base, edible oils, emulsifiers, concentrated soup, cheese and so on. Collaborate, set up a set of cooling methods suitable for your products, and a complete system that integrates the feeding and discharging equipment.

Chocolate shaped steel strip steamed cake furnace chocolate granulation

Contact freezer for meat, seafood and coffee concentration

The Consol wind refrigeration system uses the special properties of the steel strip to bring lower production cost and processing time, thus providing higher standard quality.

The steel belt has excellent thermal conductivity, smooth and unbonded surface (bringing the highest hygienic standard), and smoothly and cleanly unloading from the ends of the steel strip (minimizing waste and breakage).

These are more economical and greatly improve the processing efficiency. The blast freezing and defrosting and automatic strip cleaning function combination, so that the system has more functions, more health, able to handle like hamburger pie, fish, shrimp and poultry block, freeze-dried coffee, tea extract, baby food products such as.

The refrigerator can handle all these products. It is reliable, economical, large production and low cost.

Chocolate shaped steel strip steamed cake furnace chocolate granulation

Contact freezer for meat, seafood and coffee concentration

The Consol wind refrigeration system uses the special properties of the steel strip to bring lower production cost and processing time, thus providing higher standard quality.

The steel belt has excellent thermal conductivity, smooth and unbonded surface (bringing the highest hygienic standard), and smoothly and cleanly unloading from the ends of the steel strip (minimizing waste and breakage).

These are more economical and greatly improve the processing efficiency. The blast freezing and defrosting and automatic strip cleaning function combination, so that the system has more functions, more health, able to handle like hamburger pie, fish, shrimp and poultry block, freeze-dried coffee, tea extract, baby food products such as.

The refrigerator can handle all these products. It is reliable, economical, large production and low cost.

A dehydrating drying device for fruits and vegetables

The steel belt is used in the drying system for efficient and hygienic drying of many kinds of food. The system has a number of advantages, including greater processing efficiency, less bacterial count, optimal drying cycle configuration, and more saving operating costs.

Significant performance advantages

The unique steel strip dehydration system of Ken Shao has the following significant performance advantages:

The processing time is reduced by up to 50%.

Modular design allows different units to be connected to a multistage dryer, providing the best time / temperature configuration for each product.

The air flow system can effectively inhibit the production of non - needed product dust.

The minimum cost of production is due to lower power consumption and lower labor demand.

It may be the highest level of health at present, and the total number of bacteria / yeast / mold is much lower than that of other continuous drying methods.

Excellent product quality and appearance

Food steaming line

The steel strip type tunnel steaming furnace can be used for automatic cooking of many kinds of food. The most typical applications are steamed cake, steamed sandwich and automatic steamed bread production line.

Steel belt and steel belt conveying system

In the food processing industry, the advantages of the steel strip are well known; the most widely used technology today can not be achieved at all if we leave our steel strip. In the oven system, our steel belt brings good heat resistance, smooth surface, the product can be easily removed, and easy to clean. On the meat cutting table, it provides strong, durable surface, complete health and corrosion resistance.

But behind the excellent performance of the steel strip, we have a professional support for engineering support to make it an ideal choice for storage and accumulation in the process. Products can be stored in time, for example, between processing and packaging, and feed to the next production line as needed, which will not cause any possible damage in traditional batch storage and transmission process.