MS1650 precipitation hardening stainless steel is a low carbon martensitic stainless steel based on chromium,nickel and copper. It has high strength characteristics, good corrosion resistance and slight deformation under heat treatment. Besides, this steel belt has a good maintainability.

Static strength(Normal temperature)

|

Perameter

|

Yield strength

Rρ0.2

|

Tensile strength

Rm

|

Ductility

|

Welding

index

|

Hardness

|

|

Mpa

|

Mpa

|

A5(%)

|

Rm

|

HV5

|

Parent material

|

1550

|

1650

|

4

|

0.85

|

490

|

|

Welding area

non-heating

|

1100

|

1150

|

*

|

*

|

*

|

|

Welding area

after heating

|

1250

|

1300

|

*

|

*

|

*

|

Steel belt characteristics

●Hard surface and good abrasion resistance.

●The steel belt is smooth and uniform.

●Excellent fatigue resistance.

●Good corrosion resistance.

●Easy to stretch.

●Easier to maintain

●High welding coefficient, after special treatment,

Dynamic strength

The definition of fatigue limit is that under a certain alternating stress, 50% of the test samples can withstand the load cycle of 2 million times. Test at 20 ℃ dry environment, the fatigue limit of parent metal is + 630 N/mm squared (91 Ksi).

Corrosion resistance

MS1650 shows good corrosion resistance under normal air conditions. However, the steel belt should not be applied to the environment with hydrochloric acid.

chemical component

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Ni

|

Cu

|

Ti

|

Mo

|

0.073

|

1.53

|

0.69

|

0.0062

|

0.002

|

13.56

|

7.09

|

0.71

|

0.48

|

0.88

|

weldability

MS1650 steel belt has good welding performance, and the weld has good strength and toughness. The welding wire is the best for ER632 and ER630, and the ideal welding method is TIG welding. Even if there is no weld heat treatment, there is good strength. Guangzhou kenshao has the ability to heat heat treatment on site, and the welding coefficient is close to 0.9 by welding heat treatment.

The application of martensitic stainless steel to double steel belt presser

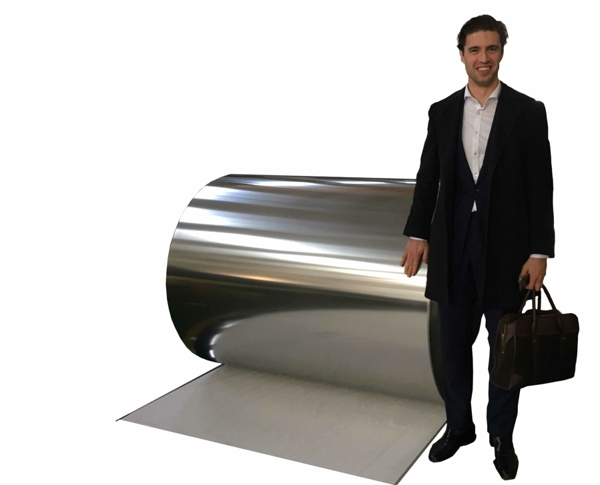

Scope of supply

Scope of supply

Length: customizable

Width: 1000/1200/1500/2000/3000/4000.

Thickness: 1.0/1.2/1.9/2.2/2.7.

The width of the single steel band is 1500mm, which is more than that. Special specifications can be customized.

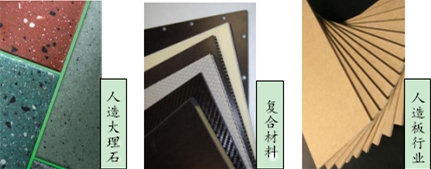

Application products

The stainless steel belt is made of high strength steel which has excellent mechanical properties and good corrosion resistance. It is the best choice for producing under harsh production condition. Easy to maintain is an added advantage.

It is suitable for pressing or forming double steel belt presser, single steel belt presser and sheet pouring system for materials such as plastic, fiber composite and various films.

Double steel belt press, single steel belt press and sheet casting system include the following technological process, product type and process application:

Drum vulcanization machine: transmission belt heavy conveyor belt, printing rubber blanket, rubber and plastic floor, waterproof rolling material.

Pressure/laminate: fiber composite, metal composite, composite floor, film, insulation board.

Sheet casting: engineering stone/synthetic marble, thermoplastic sheet (PE, PP,PA, PVS, PET, etc.)

film&sheet casting: fiber film, ceramic film, solar energy and fuel cell membrane.

Artificial board press