Location:Home > News > Industry Dynamics

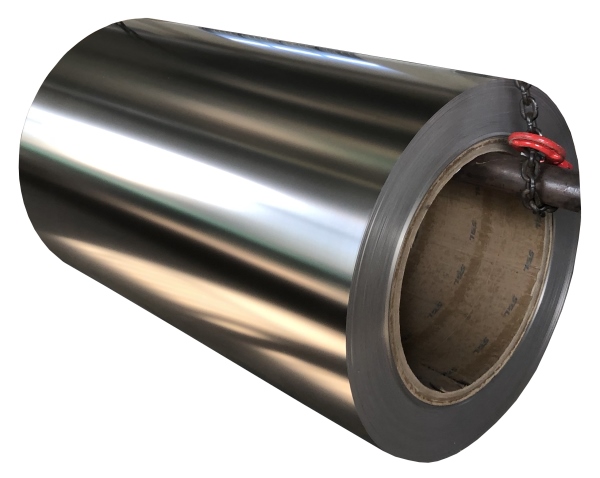

Common sense description of stainless steel coil surface

2019/2/27 15:18:06

N0.1 heat-treated and pickled after hot rolling。

2B After cold rolling, heat treatment, pickling or similar treatment, and finally flattening to obtain appropriate gloss。

2D heat-treated after cold rolling, pickling or similar or matte surface。

HL Polishes abrasive materials with appropriate grain size to make the surface continuously grained.

In order to ensure that the mechanical properties such as yield strength, tensile strength, elongation and hardness of various types of stainless steel coils meet the requirements, stainless steel coils must be subjected to heat treatment such as annealing, solution treatment and aging treatment before delivery. The corrosion resistance of stainless steel coils mainly depends on its alloy composition (chromium, nickel, titanium, silicon, aluminum, etc.) and the internal structure of stainless steel coils. The main role is the chromium element. Chromium has high chemical stability, can form a passivation film on the surface of steel, isolate the metal from the outside world, protect the steel plate from oxidation, and increase the corrosion resistance of the steel plate. Corrosion resistance decreases after the passivation film is destroyed。